The maker craft movement has transformed how creative entrepreneurs build products and businesses. Whether you’re pressing your first sublimation tumbler or running a full studio with lasers and heat presses, the right blanks, tools, and strategies can mean the difference between hobby-level earnings and professional income.

This guide is for creative entrepreneurs, hobbyists, and small business owners looking to turn their maker craft skills into a profitable venture. Maker craft empowers individuals to create unique, personalized products and build sustainable businesses in the modern creative economy.

This guide walks you through everything from choosing wholesale suppliers to organizing your workspace—helping you earn more per hour from the work you love. This is great for adults and parents.

- What Is Maker Craft?

- Wholesale Maker Craft Blanks & Supplies

- Best-Selling Maker Craft Tumblers & Drinkware

- Essential Tools for Maker Craft: Printers, Cutters & Lasers

- Maker-Ready Blanks, Resins & Glitter for Advanced Projects

- Featured Makers & Community Inspiration

- Increasing Profitability in Maker Craft

- Finding Your Niche as a Maker

- Organizing Your Maker Craft Space & Workflow

- Beginner Maker Craft Projects to Get Started

- Turning Maker Craft into a Profitable Business

What Is Maker Craft?

Definition: Maker crafts refer to a modern subculture blending traditional crafting with DIY, technology, and engineering. Maker crafts focus on tinkering, which is an iterative process of building, testing, and adapting.

Maker craft sits at the intersection of DIY creativity, small-batch manufacturing, and product customization. It’s the practice of using accessible desktop tools—sublimation printers, laser engravers, vinyl cutters, and heat presses—to transform blank products into personalized, sellable goods.

Since around 2015, maker craft has exploded alongside platforms like Etsy and Shopify. Affordable machines from brands like the Cricut Maker series, Glowforge lasers, and Epson sublimation printers have put professional-grade production within reach of home-based creators. What once required factory equipment now fits on a craft room table.

This guide helps you discover the right blanks, invest in reliable tools, and build business strategies that maximize your profit per project.

What maker craft includes:

- Custom tumblers and drinkware (stainless steel, glass, ceramic)

- Vinyl decals for cars, walls, and products

- Sublimation apparel, mugs, and home décor

- Laser-engraved cutting boards, signs, and keychains

- Resin art including glitter tumblers, coasters, and jewelry

- Heat-transfer designs on bags, hats, and accessories

Maker Craft: A Foundational Overview

Maker crafts refer to a modern subculture blending traditional crafting with DIY, technology, and engineering. This movement is characterized by a focus on tinkering—an iterative process of building, testing, and adapting. Common maker craft areas include metal-working, jewelry making, filmmaking, and robotics. This foundational context helps explain the diversity and innovation found within the maker craft community.

Wholesale Maker Craft Blanks & Supplies

Buying blanks at retail prices eats into your margins quickly. When you order wholesale—typically 25 or more units—you unlock pricing that can transform a break-even project into a profitable one. Most suppliers offer tiered discounts that stack with seasonal promotions, making bulk purchasing essential for serious makers.

Key product categories to stock:

- Stainless steel tumblers in standard sizes: 12 oz skinny, 20 oz straight, and 30 oz tapered are the most versatile for sublimation and vinyl

- Glass can tumblers with bamboo lids—these have become bestsellers since 2022 for iced coffee aesthetics

- Sublimation-ready mugs with bright white coatings that absorb ink cleanly

- Wood boards and blanks for laser engraving: cutting boards, coasters, ornaments, and signs

- Sublimation polyester blanks including pillowcases, tote bags, and mousepads

Wholesale purchasing strategies:

- Save around 10–20% when ordering tumblers or sublimation blanks by the full case

- Case quantities ensure consistency in coating thickness and color matching across batches

- Look for laser-ready wood that comes pre-sanded and ultra-flat to reduce prep time

- Mix-and-match minimums (25+ units across styles) often unlock the same discounts as single-SKU orders

- Stock up during seasonal sales—many suppliers run deals around Black Friday, end-of-quarter, and summer slowdowns

Start with sample packs before committing to large orders. Once you know which blanks perform best with your equipment, scale up to wholesale quantities.

Best-Selling Maker Craft Tumblers & Drinkware

Tumblers became a core product for makers around 2018 and haven’t slowed down. They’re everyday items people actually use, they photograph well for social media, and customers perceive them as high-value gifts worth the money.

The drinkware category offers something for every skill level and equipment setup.

Popular tumbler and drinkware formats:

- Skinny stainless steel tumblers (20 oz) remain the gold standard for sublimation—they’re easy to wrap and display designs beautifully

- Handled mugs (12–14 oz) appeal to coffee drinkers who want a traditional grip

- Wine tumblers with stemless designs work for bachelorette parties, teacher gifts, and everyday use

- Glass cans with bamboo lids sublimate or engrave cleanly and have an amazing aesthetic that photographs well

- Kids’ tumblers (12 oz with straws) sell consistently for back-to-school and birthday parties

Material and coating considerations:

- Look for 304-grade stainless steel for durability and food safety

- Borosilicate glass resists thermal shock better than standard glass

- “Perfectly coated” sublimation tumblers are engineered to absorb ink vibrantly with full-wrap designs

- Double-wall vacuum insulation is expected at most price points now

Smart purchasing approaches:

- Start with sample packs of 5–10 pieces to test how blanks perform with your specific printer and press

- Move into bulk orders of favorite sizes once you have sales data showing what customers actually order

- Many suppliers offer 10% off when mixing and matching 25+ individual tumblers in a single cart

- Track your stock levels—running out of your bestseller during a holiday rush costs more than the storage space

Essential Tools for Maker Craft: Printers, Cutters & Lasers

Your equipment is the workhorse of your maker craft studio. Investing in reliable machines—even if they cost more upfront—pays off in fewer failed projects, consistent output, and less time troubleshooting.

Sublimation printer options:

- Entry-level converted EcoTank printers (Epson ET-2850, ET-15000) work well for beginners with lower upfront costs

- Dedicated sublimation units like the Epson SureColor F170 or F570 offer better color accuracy and are designed for sublimation ink from the factory

- Upgrade from a converted printer when you’re consistently producing 20+ items per week or need wider format capability

- Consider ink costs per print—dedicated units often have more efficient ink delivery systems

Desktop cutting machines:

- The Cricut Maker and similar cutting machines handle vinyl decals, cardstock, felt, and thin wood veneers

- These complement sublimation by letting you cut HTV (heat transfer vinyl) for items that can’t be sublimated

- Blade quality matters—keep spare blades in stock so a dull blade doesn’t slow production

- Software subscriptions (like Cricut Access) provide design libraries but aren’t required for basic operation

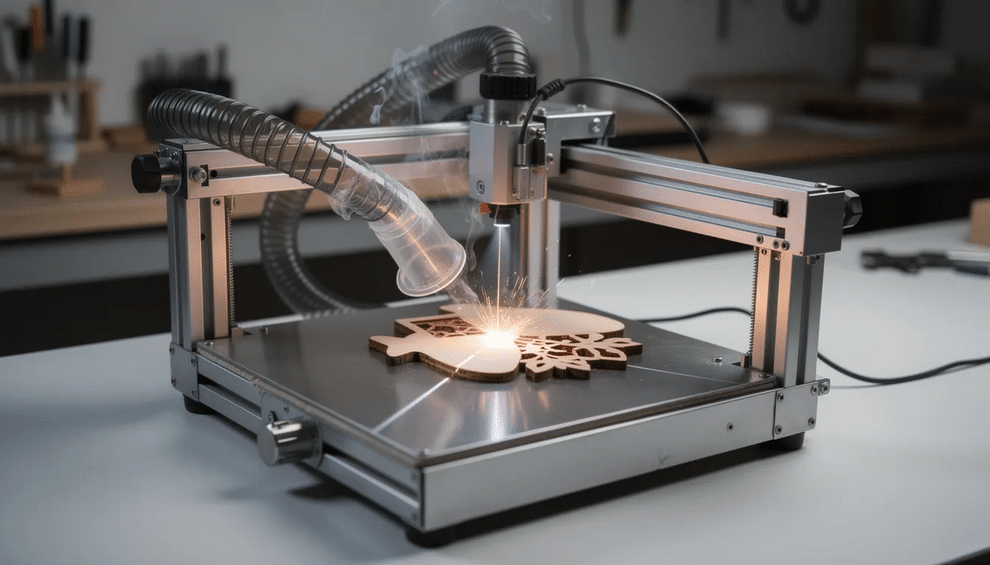

Laser engravers and cutters:

- Entry-level CO₂ lasers (40W–60W) handle wood, acrylic, leather, and coated metal marking

- Diode lasers are more affordable but limited to thinner materials and slower speeds

- Check bed size before purchasing—a 12×20 inch bed handles most small products; larger beds add flexibility

- Exhaust requirements matter: plan for ventilation to the outdoors or invest in a quality filter system

- Software compatibility (LightBurn, LaserGRBL) affects your learning curve and file workflow

Supporting equipment and add-ons:

- Heat presses (15×15 inch is standard; consider a swing-away design for safety)

- Convection ovens or mug presses for tumbler wraps with shrink sleeves

- UV DTF printers for transferring full-color designs to hard surfaces without sublimation coatings

- Hand tools: weeding tools, scrapers, craft knives, heat-resistant tape, and silicone mats

- Power strips with surge protection—your equipment represents a significant investment

Maker-Ready Blanks, Resins & Glitter for Advanced Projects

As your skills grow, you’ll likely expand beyond basic sublimation into resin, glitter, and mixed-media work—projects that often require art supplies tailored to your needs. These projects command higher prices and attract customers looking for truly unique, handcrafted pieces.

Understanding maker-ready blanks:

“Maker-ready” means the blank arrives prepared for immediate customization. Wood is pre-sanded and sealed. Tumblers have spray coatings applied evenly. Surfaces are sized to fit common machine beds. You unwrap and start creating without hours of prep work.

Popular resin projects:

- Glitter tumblers with epoxy coatings that create depth and sparkle

- Keychain blanks with bezel settings for pour-and-cure designs

- Coaster sets using silicone molds and decorative inclusions

- Tray inserts and serving boards with river-table-style pours

Glitter and material considerations:

- Specialized craft glitter (fine, chunky, holographic) won’t bleed color into epoxy

- Formulations designed for drinkware withstand hand washing and daily use

- “Craft-grade” glitter differs from cosmetic glitter—use appropriate types for each application

- Epoxy resins with clear cure dates ensure predictable working time and hardness

Safety essentials for resin work:

- Respiratory protection (N95 minimum; organic vapor respirators for heavy use)

- Adequate ventilation—work near an open window or use an exhaust fan

- Follow cure time instructions exactly; rushed cures create soft or tacky surfaces

- Keep work surfaces protected with silicone mats or disposable coverings

Featured Makers & Community Inspiration

Seeing real makers build successful businesses helps newcomers understand what’s possible. The range of niches and styles in maker craft means there’s room for many approaches—from high-volume production to boutique custom work.

Example maker profiles:

- A sublimation mug specialist from Texas built her business around teacher appreciation gifts, producing 200+ mugs per month during back-to-school season using an Epson F570 and 15×15 heat press

- A resin tumbler artist from Florida focuses exclusively on beach-themed glitter cups, photographing products with natural sand and shell props that drive Instagram engagement

- A laser-engraved cutting board business started in 2020 grew from farmers market tables to wholesale accounts with regional kitchen stores using a 50W CO₂ laser

What successful makers have in common:

- They chose a specific niche instead of trying to sell everything

- They invested in photography and consistent branding

- They built email lists and repeat customer relationships

- They’re active in maker communities for troubleshooting and inspiration

Where to connect with maker communities:

- Instagram hashtags: #sublimationcrafts #lasercrafts #tumblerbusiness

- Facebook groups focused on specific machines or techniques

- YouTube channels with tutorials from working makers (not just reviewers)

- Local craft fairs where you can meet makers in person and see their setups

Increasing Profitability in Maker Craft

How Makers Increase Profit Per Hour

Your blanks and machines are only part of the equation. How you structure your workflow and price your products determines what you actually earn per hour of effort.

Five areas that dramatically improve hourly profit:

- Batch similar orders together: Producing 24 tumblers in one session (same design, same size) takes far less time per unit than making them one at a time

- Raise prices to reflect reality: Calculate materials, labor at a fair hourly rate, overhead, and profit margin—then price accordingly instead of copying competitors

- Standardize your bestsellers: Create templates and saved settings so repeat orders require minimal setup

- Pre-make inventory: Produce popular designs before orders come in so you can ship faster and work during efficient production windows

- Use design templates: Save color palettes, font pairings, and layout structures in your design software to speed up custom work

The math on batching:

Making one tumbler from start to finish might take 45 minutes including setup, pressing, and cleanup. Making 12 of the same tumbler takes maybe 2.5 hours total. Your per-tumbler time drops from 45 minutes to about 12 minutes—nearly 4x improvement in production efficiency.

Look for educational workshops and online classes (many created between 2022–2024) that teach professional pricing strategies. The difference between hobby pricing and business pricing often means the difference between burnout and sustainability.

Finding Your Niche as a Maker

Finding Your Niche in Maker Craft

Trying to sell everything to everyone is the fastest path to getting lost in marketplace noise. The makers who build recognizable brands focus on specific product lines, audiences, or aesthetics.

Validating demand before committing:

- Search Etsy for your product idea and note how many listings exist and their review counts

- Browse local Facebook buy/sell groups to see what handmade items generate comments and interest

- Attend craft fairs between spring and holiday season to observe what sells and what sits

- Ask friends and family what they’d actually pay for (not just what they say is “cute”)

Narrowing by audience and medium:

- By audience: Teachers, nurses, sports fans, pet owners, bridesmaids, new parents

- By medium: Sublimation, vinyl, laser engraving, resin, or combinations

- By aesthetic: Minimalist, maximalist glitter, rustic farmhouse, modern geometric

- A clear niche makes marketing easier—your ideal customer recognizes your products instantly

Seasonal launch opportunities:

- Valentine’s Day mugs and wine tumblers (design in December, sell in January)

- Summer pool tumblers and beach cups

- Halloween glow-in-the-dark and spooky-themed drinkware

- Winter holiday ornaments, teacher gifts, and family reunion orders

- Plan 6–8 weeks ahead for each season to allow production and marketing time

Organizing Your Maker Craft Space & Workflow

A dedicated, organized space doesn’t just look professional—it directly impacts how many orders you can complete without errors. When orders increase, every minute spent searching for materials or clearing workspace costs you money.

A simple 4-zone organization framework:

- Blank storage: Where raw materials wait before production

- Active workspace: Where cutting, pressing, and engraving happen

- Curing/drying zone: Where items cool, cure, or dry before packaging

- Finished inventory and shipping: Where completed products await orders

Practical storage solutions:

- Labeled clear bins for blank tumblers sorted by size and color

- Drawer units for vinyl rolls, transfer tape, and decal sheets

- Wall-mounted racks for cutting mats, rulers, and heat-resistant tape

- Rolling carts that move between zones as needed during production

- Pegboards for weeding tools, scissors, and frequently-used hand tools

Safety zones for heat and laser equipment:

- Keep heat presses and lasers away from flammable materials (vinyl, paper, packaging)

- Create clear ventilation paths—don’t block exhaust vents with storage

- Position a small fire extinguisher within reach of laser equipment

- Ensure accessible power outlets to avoid running extension cords across walkways

- Consider dedicated circuits for high-draw equipment to prevent tripped breakers

Digital Design & File Management

Digital organization saves as much time as physical organization. When you can locate any design file in seconds, you eliminate one of the most frustrating bottlenecks in custom production.

Essential design tools:

- Canva or similar for quick photo layouts, social media graphics, and mockups

- Adobe Illustrator, Affinity Designer, or CorelDRAW for vector work that scales without pixelation

- Free alternatives like Inkscape work for basic vector needs

- Machine-specific software (Cricut Design Space, LightBurn) for production-ready files

File organization structure:

- Create folders by year, then product type, then individual projects

- Use consistent naming: “2025_Tumblers_TeacherAppreciation_Final.png”

- Keep source files (.ai, .svg) separate from print-ready exports (.png, .pdf)

- Maintain a “Templates” folder with reusable layouts, fonts, and design elements

Building a reusable asset library:

- Save your 10 most-used fonts in one easily accessible folder

- Create a brand color palette file you can import into any project

- Collect pattern backgrounds, icons, and decorative elements that match your style

- Screenshot your printer and press settings for different substrates as reference files

Beginner Maker Craft Projects to Get Started

You don’t need expensive equipment or bulk inventory to make your first maker craft projects. Start with low-risk, low-cost items to build skills and test whether customers respond to your style.

Five starter projects for new makers:

- Vinyl decal mug: Apply pre-cut vinyl to a dollar store ceramic mug. Time: 20–30 minutes. Tools: basic craft knife, transfer tape, vinyl scraps.

- Sublimation skinny tumbler: Use a pre-made design from a licensed digital shop, print on sublimation paper, and press. Time: 30–45 minutes including setup. Tools: sublimation printer, tumbler press or shrink wrap with convection oven.

- Laser-engraved wood keychain: Purchase pre-cut keychain blanks and engrave a simple name or design. Time: 15–20 minutes per batch. Tools: entry-level diode or CO₂ laser.

- Resin-coated glitter pen: Dip or brush epoxy onto a pen blank with embedded glitter. Time: 30 minutes active plus 24-hour cure. Tools: epoxy resin, craft glitter, pen blanks.

- Heat transfer vinyl t-shirt: Cut and weed a simple design, then press onto a blank shirt. Time: 30–45 minutes. Tools: cutting machine, heat press or household iron.

Using first projects strategically:

- Photograph every finished piece for your portfolio, even practice items

- Gift or sell first projects to friends to gather real feedback

- Bring samples to a local craft fair to gauge customer interest before investing in inventory

- Post work-in-progress content on social media to document your learning journey

Turning Maker Craft into a Profitable Business

Many people who started maker craft as a pandemic hobby between 2020 and 2024 now run legitimate side businesses or full-time operations. The path from hobbyist to professional requires intentional decisions about pricing, sales channels, and product focus.

Pricing that actually works:

- Calculate true material cost per item (blank, ink, vinyl, packaging, shipping supplies)

- Add labor at a realistic hourly rate ($15–25/hour minimum for skilled work)

- Include overhead: equipment depreciation, electricity, software subscriptions, marketplace fees

- Add profit margin on top—typically 20–40% depending on market positioning

- Never price by simply matching or undercutting competitors; their prices may be unsustainably low

Sales channels to consider:

- Etsy: Largest handmade marketplace; high competition but built-in traffic

- Personal website (Shopify, WooCommerce, Squarespace): Higher margins, full brand control

- Local boutiques and gift shops: Wholesale accounts provide steady volume

- Craft fairs and markets: Direct customer feedback, no shipping hassles, cash flow

- Corporate and custom orders: Team gifts, event swag, and promotional items at higher quantities

Building repeat business:

- Create product bundles: bridesmaid sets, family reunion packages, team orders

- Launch seasonal collections that customers anticipate and pre-order

- Collect email addresses and notify previous buyers about new designs

- Offer loyalty discounts for customers who return within 90 days

The makers who succeed long-term click into a rhythm of consistent production, smart pricing, and genuine connection with their customers. It’s not about working more hours—it’s about making each hour count.

Your 90-day action plan:

- Choose one focused product line based on your current skills and equipment

- Set up a simple online storefront (Etsy is fine to start)

- Create 5–10 listings with quality photos and clear descriptions

- Price using the formula above, not guesswork

- Commit to 90 days of consistent effort before evaluating results

- Track what sells, what doesn’t, and what customers ask for

- Refine designs, adjust pricing, and expand based on real data

The maker craft community continues to grow because the fundamentals work: people want unique, personalized products created with care. With the right blanks in stock, reliable tools humming along, and a clear plan for your business, you’re positioned to turn creative work into sustainable income.

Start with one product. Perfect your process. Then scale what works.